CASE STUDY

Machine panel

The challenge facing our team in this case study is taking a client’s bespoke, and tricky to bend, part and re-engineering it for batch production. The machine panel cover involves some complex bends, and detailed finishing

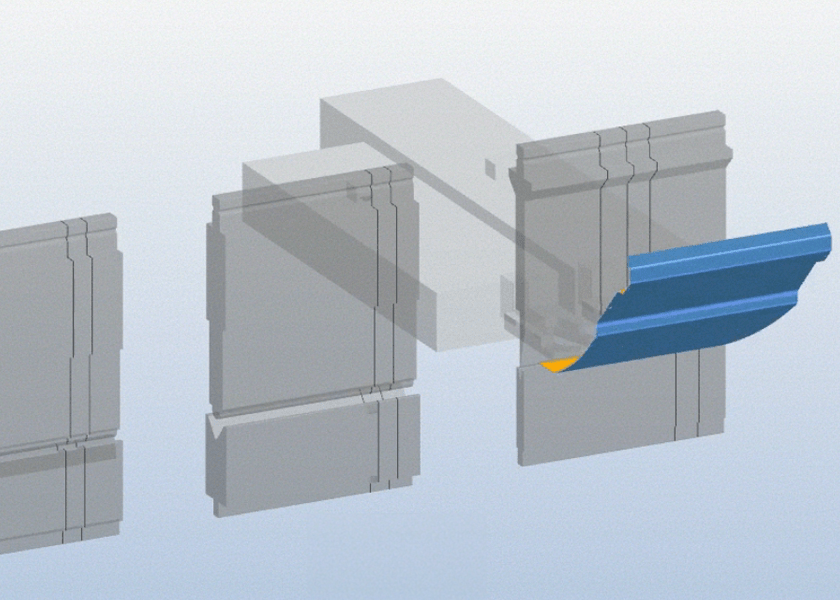

CAD programming

As the design for the new iteration of the machine panel cover has to be repeatable, and easy to batch produce, the CAD engineers utilised the new software attached to our newly installed Press Brake machinery.

The software allows the team to visualise the bends in a 3D process video, to enable development of the drawings to make production as smooth as possible.

Laser cutter

After the design was finalised, the part headed to the laser cutter to be batch produced. The laser is able to easily cut the 2mm aluminium sheet the machine panel part is made from, and the quick speed and thinness of the sheet metal means we can easily process this part in full automation on the laser cutter.

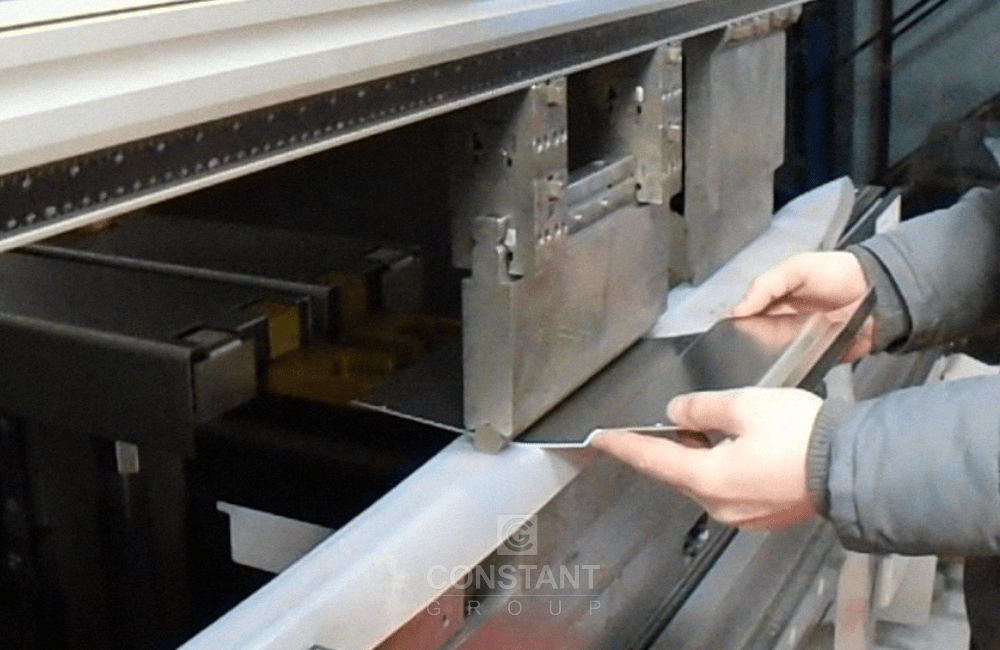

Precision press brake bending

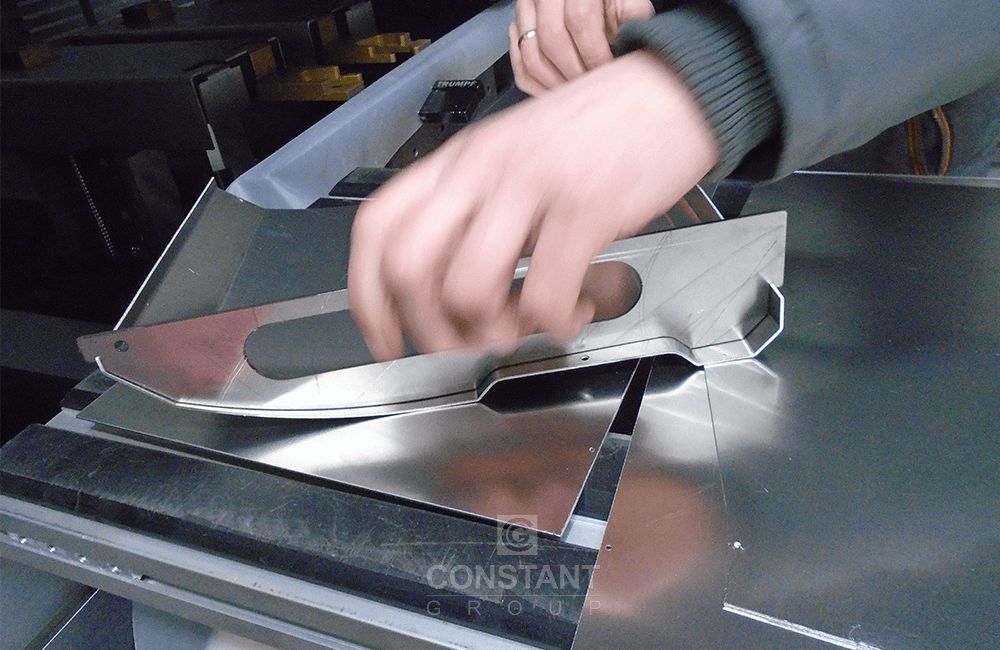

Once cut, it was time for those bends. If the large radius bend was formed in a traditional manner it would involve a rolling machine and would leave a flat edge and not allow for the other complex bends to be formed all in one smooth process. The press brake supervisor took the part and followed through the already programmed bend sequence from the CAD engineers. The new machine even highlights where the part should be placed and moved through small LED guidance lights. This is advantageous for newly qualified operators, vs our experienced press brake supervisor featured in the video.

He then takes a bend jig to check all the bends have been formed in the correct way. This jig allows the repeat-ability of the panel to be as accurate as possible and each item quality checked immediately to prevent any production errors.

Powder coating

The parts then head to our powder coating plant to get a coat of textured orange paint. The orange is colour matched to the customer’s original bespoke part, and the textured finish gives it a longer shelf-life as it is more durable than a gloss smooth white finish. We’ve zoomed into the finish so you can see the slight textured appearance through the reflection of the factory lights.

Final machine panel part

For what looks like a ‘simple’ part, it is far more complex and involves expert CAD engineering to make sure it goes from cut to bend smoothly on a large production scale.