Case studies

From telecom cabinets to food production funnels, our case studies are a snapshot of the capabilities of Constant Group’s design and manufacturing.

Telecoms Enclosure

These cabinets are enclosures that wrap around a telephone mast to house equipment for the mast. This telecoms enclosure is made from pieces of stainless steel with a powder coated finish.

Electric Box Part Samples

A case study with a difference; giving an overview of how we go through the design, sampling and manufacturing process using various form tools, hinged component design, machine and fast bends for an internal electrical box for an air conditioning unit.

Modular Retail POP Kiosk

A freestanding kiosk point of purchase display stand that can be disassembled into a tabletop version, given it versatility as well as function.

DOOH Display

Take a look at how we redeveloped and manufactured a freestanding digital out of home (DOOH) display for a retail display customer. The DOOH stepped through every section of our manufacturing site from CAD Design and laser cutting, through to powder coating and assembly.

Mobile DOOH Display

A redevelopment of a client’s existing mobile totem display with the instructions to be easier to move, lighter to move, and constructed with additional features such as keyless operation.

Machine Electrical Cabinet

Precision design, immaculate finishing and swift manufacturing were required for a new electrical cabinet/box for an automated production machine.

Outdoor Sport Lighting Unit

Our metal outdoor lighting case study looks at the design, punch and assembly of a sport lighting unit, that had to be bug proof, weatherproof and efficient to manufacture. The unit also sports safety bends and no welded edges.

POS Case Study

We were approached to take a 3D visualisation render of a retail POS display by our client and create it into reality. The end display unit was made completely in-house at Constant from design to delivery.

Food Production Funnel

Our CAD engineers worked closely with our press brake team to take a 2mm thick piece of steel and bend it with precision, to create a perfect funnel for a food production client.

Panel Cover

This machine panel cover may look like a ‘simple’ part, but it is far more complex involving expert CAD engineering and programming of our press brake machines, through to detailed tricky screen printing. All to make sure it goes from cut to bend smoothly on a large production scale.

Magnet Display

Made from Zintec, this counter top rotating display incorporates a lazy Suzanne mechanism and a gloss black powder coating finish. The end product is a discreet shop counter-top display to hold kitchen magnets.

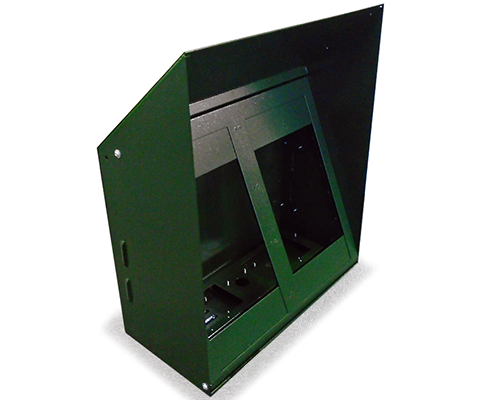

Interactive Display Unit

A set of metal interactive display units from several pieces of metal, with ancillary components supplied by the customer such as; hard drives, fans, routers and a touch screen display.

IoT Interactive Display Unit

A case study looking into the manufacture of freestanding Internet of Things units that we designed and manufactured for a kiosk printing solutions company. They were after several units that could house a Microsoft Surface Pro securely, as well as a bulky printer.

Large Security Cabinet And Safe

This large cabinet measures over 1500mm in height, 160kg in weight, and was manufactured from 7 sheets of steel. A formidable project that we took from CAD design and prototyping into full production and assembly.

Metal CCTV Arm And Bracket

A camera arm with metal fixing bracket went through the factory floor involving a few unique elements from steel tube fast bends through to HR4 versus the usual CR4 steel.