CNC bending

Making precision sheet metalwork look easy with metal forming tools such as our CNC press brake machines and rolling machines

ByStronic

CNC Bending/Press Brakes

We have 8 precision sheet metal bending machines on Constant’s shop floor including new touch screen controlled Bystronic Xpert 100s, all programmed offline.

We also have rolling machines as part of our sheet metal fabrication facilities. This allows us to bend lengths on the shop floor from as small as a matchstick to 3 metres in lengths.

For jobs that require tight bending tolerances, we have a range of machines that are equipped with automatically controlled bending sensors. These allow precise and fast angle measuring throughout the bending procedure with the facility to make micro adjustments automatically, to keep the machine producing the desired angles to extreme accuracy.

- Offline programming of bending

- 4 and 6 axis machines

- Complex bends can be produced reducing reliance on multiple weld parts

- We can bend as small as a matchstick and up-to 3 metres in length

- Bending as thin as 0.7 mm as standard, with capabilities for thinner materials on site as specials

About Our Press Brake Capabilities

Utilising up-to-date, 6 axis press brake technology, we can process simple parts to intricately formed precision components on our Bystronic Xpert 100s and TruBend 5130 machines. Our press brake machines have back stops completely independent of each other, which makes them ideal for bend lines that are on an angle or for parallel short stop edges, that are displaced to each other in the working plane.

Our suite of press brakes are equipped with 3D graphical display and programming; ideal for ease of CAD engineering where complicated folding sequences are taking place and need to be visualised before deployment onto the factory shop floor.

Case Studies

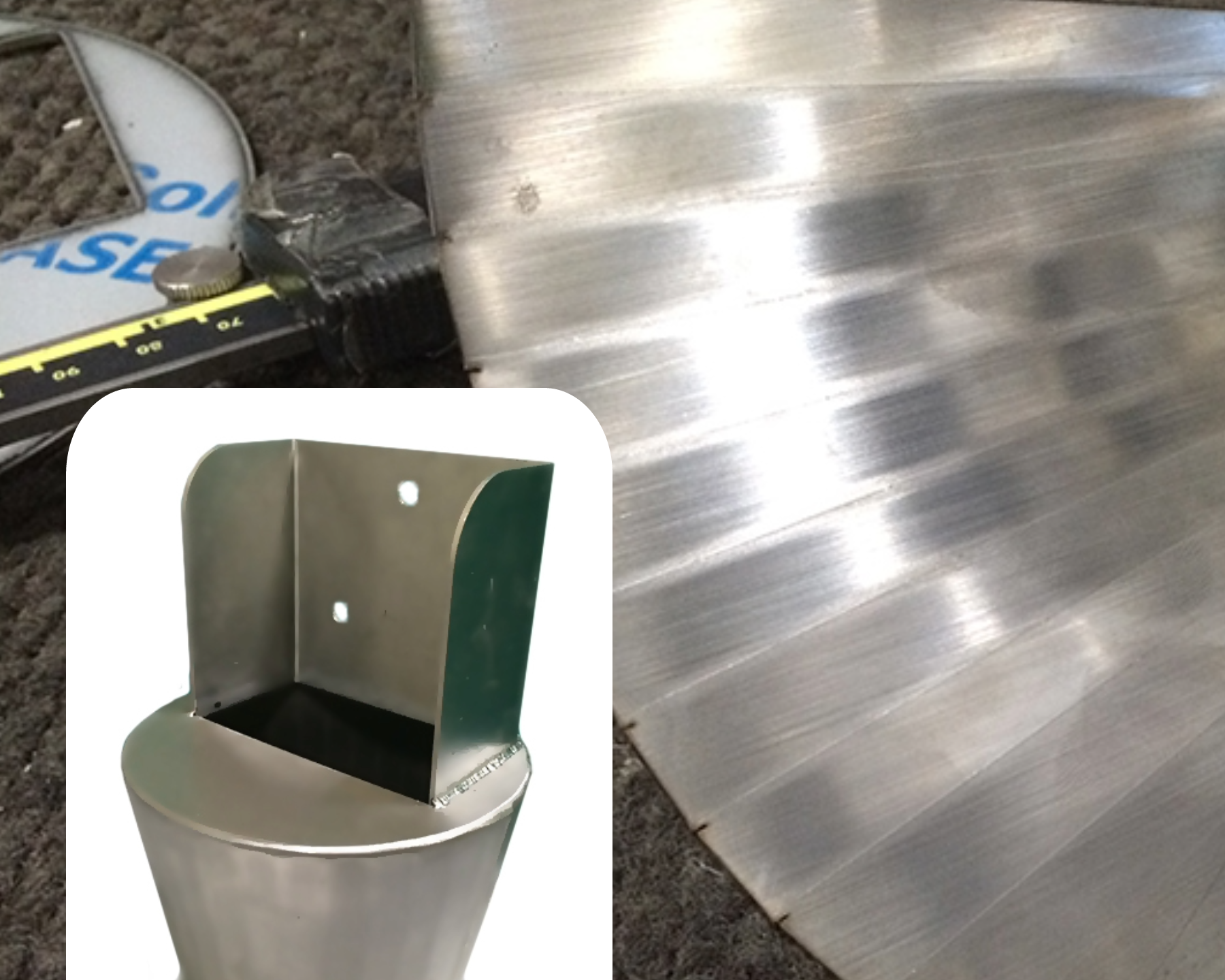

Machine Panel Cover

Formed on one of our new Bystronic Press Brakes, this machine panel cover involved a large radius bend, that otherwise would of been to be formed on a traditional roller, leaving a flat edge.

Metal Food Production Funnel

A 2mm stainless steel funnel, that involved precision programming and bending from start to finish to ensure tight fit and accuracy as it is integrated into a larger food production unit.

Electric Box Part Samples

An overview of how we go through the design, sampling and manufacturing process using various form tools, hinged component design, machine and fast bends.